INDUSTRY AND COMMERCE

As I am no industrialist and not much of a businessman, this may seem like an unlikely subject to find here, but some of these comments may be of interest over time.

As kids we used to scour the rubbish dumped near where we played for bottles to take back to the shops for cash. The bottles were recycled by severe mechanical washing. Recycling is not as literal any more, being more to do with the materials rather than the items themselves. The dad of the George boys (we shared cousins through Elise Watson nee Kockett) worked for Coca Cola and we once got a look around the plant. We would also seek out bottle tops that had inner seals that had promotional offers that could be traded in for yoyos, small African animals or birds etc. Or we could get some cents and buy bubble gum!

My father Brian had been City Architect for the council and had done projects such as the Guild Theatre and the Orient Beach complex. In 1964 he left to establish his own practice in the Permanent Building Society building. This progressed to larger premises in the Murray and Stewart Centre on an upper floor with great views of the city. I joined him once graduated. We had several staff and for some years, my mother was office administrator / secretary. It was at this time that we

sought out new junior staff which we were prepared to train up from scratch as draftsmen or women. We were the first in the city as far as I know in taking on some of other races and soon had two black, one coloured and one Indian guys. Such labels are now irrelevant. Back then it was very unusual. Some struggled, but others did well in this or completely different fields such as teaching. It was after a few years here that we designed and built the premises in Devereux Avenue. Also see TECHNOLOGY in architecture

There was for a while a small Leyland plant in East London. It didn't produce cars. They were carted up from a plant in Port Elizabeth, dipped and spray painted here as car bodies without innards or trims in a plant that also dealt with other products, and carted back for completion. Such was the mechanisms of profit based production.

East London has the extraordinarily large and well established CDM plant (Chrysler Daimler Manufacturers) that became to have a larger GNP than the rest of the city. It was locally known as Mercedes-Benz as this was its main product, but it also handled Honda, Man Trucks etc. The C-class Mercedes was exported to the UK, it being more economic to produce right hand drive vehicles here than in Germany. The company name has varied slightly over the years. Some mechanical input was provided by an Italian company nearby called Turin Industries.

My parents got to known Mrs Gaertner, a Jewish lady who sometimes played the organ for their Christian Science church. And also her husband Hans. He had a small plastics factory in the lower part of the city making such things as plastic macs, lilos and inflatable toys known as PakaMac. My father handled the "architectural" aspects of a garden wall at their house. Then one night he learnt that their factory was on fire. Hans phoned him even before the smoke had cleared to ask him to design his new factory. Something much larger on the West Bank. This was to grow to a very successful and very large business. They branched into doing the plastic linings of CDM cars and this is where our family comes into the Mercedes Benz subject. We did a lot of work for that factory over the years as it grew and adapted. I was once in Hans's office when he casually ordered a new model of the largest Mercedes plus a C-range Mercedes over the phone.

We also worked on warehousing such as for Hendersons and for my father's cousin Noggs Newman. This latter was a sprawling old building and as with many warehouses, let out facilities to and floor space to other businesses. A big plus factor was railway access into the site, something that lost its importance both from greater road transport and from containerisation with which it integrated.

It is worth now looking back to the commercial efforts of the grandfather I never knew, Alexander Watson. One was the purchase of an engine-less cargo ship which he had towed between Durban and East London filled with coal. Another was into cattle dips and other such products. You will find that described in some detail under his own section. On the wall as I write this is a thermometer advertising St O'Gormans cattle dip. There is a story hinged on that which you find under his specific section. WATSON, ALEXANDER RICHARDS

East London had been considered as the centre of the pineapple growing industry, Bathurst towards Grahamstown being the centre of the farming side with its pineapple centre and its Giant Pineapple, an enormous structure into which you could climb. For many years almost everywhere you looked there were neat rows of pineapples growing throughout the district. Then apartheid got in the way and a major importer from Britain, Sainsbury's cancelled its orders on a matter of

principle. I briefly worked at the large canning factory in East London, well actually on a sweet factory within the premises, but it did give me a taste of the scale of the pineapple industry here. I counted at least 25 labels in several languages being applied to canned pineapples for both local and distant export.

Doing some minor work for the Berkshire stocking factory allowed us a fascinating view to the workings. Properly called Berkshire Hosiery (UK) Ltd. Rows of automated machines would weave thread hardly visible to the naked eye into a variety of products.

The practice did numerous small projects in East London and Ciskei in the form of workshops for private and government clients.

Modern Engineering

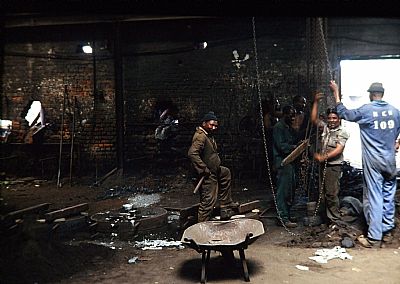

The following photos are of premises that we liaised with over the years. That was mainly to do with their excellent face bricks, but I got to see their foundry in the industrial area of central East London too. In spite of their name "Modern Engineering" the foundary clung to old methods to cast products in various metals, mainly iron and mainly manhole covers and such like. Their brickyards were on the outskirts of the city.

Methods like this remain relevant in today's world where traditional products are required. These premises worked largely from forms set in the earthern floor and also had a large collection of woodern patterns from which the earthern forms would be made. When I heard that they were going to discontinue this line of business I tried to persuade them to donate the forms to the museum - without success. I presume that they were all dumped.

My wife's cousin's wife's brother had such a foundary near London. While other still exist such as the well known Carron near Falkirk in Scotland, it is a diminishing skill. Iron is the superion metal for most of this, but others are sometimes used too. And the Far East is exporting cheap replica components into the UK such as decorative fence spikes made of aluminium.

A raw blazing furnace.

The same furnace as seen within the larger workshop premises. Tools of various kinds hang from the walls.

Moulton metal is poured into a mould. Note the "health and safety" gear!!!

When they are cool enough the forms are opened up. Excess material is gathered up for reuse.

The works were surprisingly quiet. A generator was located in an adjoining space and long drive belts flapped away driving various large pieces of equipment of unknown purpose.

The finished product, a bollard. Actually this one was sitting in storage, unused.

A whole storage room of wooden forms, both positive and negative