Sutor Trug Sailing Dinghy (Page 2)

Original drawing which was scaled up

Hull turned

Hull stitching completed ready to cut shearline

Hours taken per action2 cutout 4 transom pieces

2 mark out 1strake & stern end

2 cut 1 strake & stern end

0.75 mark out & cut 3 strakes

5 mark out & cut 4 strakes & 4 bow ends

3 Glue bow transom Make 2 butt pieces Glue two bow strakes

2.5 Glue stern trans Re-glue bow strakes butt joint (insufficient glue and pressure) Cut 3 stern end strakes

1 make 6 butt joint pieces & glue bottom panel joint using weights not nails

1 Glue 4 butt joints

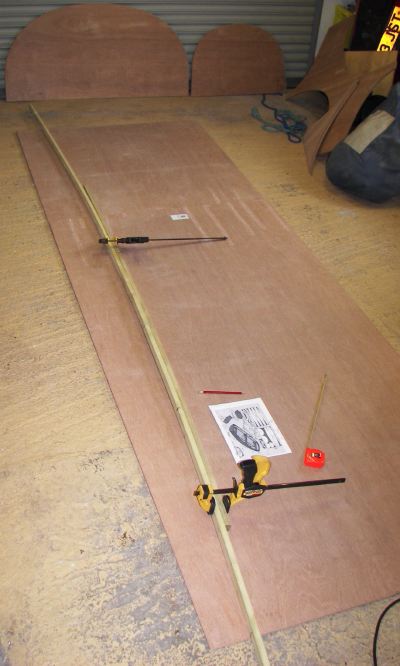

3 stack strakes and base. Tidy shed. Make jig.

2 Set up transoms and base.Part stich port strake. Check length. Measurement should be 2320.

2.5 Adjusted jig to 2320, Completed stiching port strake

1.25 Part stitch stb strake all along length. Noted chamfer requ. to reduce gaps at trans.

2.25 Shape and prepare bow trans joint. Problem in aligning edges.

2 Lined up strakes. Prepare joint by inserting nails and screws. (Next time cut off overlapping bot. panel and cut slots to relieve high joint loads). Glue with polyurathane. Glue and nail bot. Strake to support joint. Clear site.

3 Cut bow bottom. panel to relieve bend stress. Port 2nd strake wired

0.75 glue stern

0.25 correct joint error (not enough clearance in butt joint of strake)

1 Stitch 1/2 strake

2 Finish strake. Glue/nail each end of 4 strakes

1.75 Finish 3rd pt. strake. Glue/nail each end of strake

0.25 Start 3rd stb strake

2 finish 3rd strake

0.25 polyglue 1 seam

0.5 glue last two strake joints

0.5 polyglue 2 1/2 seams ran out of glue.but enough joint made to turn boat.Will complete later.

Mark out cut strakes and transoms. Butt joint bottom panel and strakes. Laminate transoms. Make jig. Set up trnasoms on jig aft vertical bow angled. Chamfer edges of transoms to fit strakes. Attach bottom panel with nails and screws. Stitch strakes and polyglue seams.

turn boat using slings from roof

total to date 48.5 hours