NEATH FLOATING DOCK

Dr Paul Richards

PART ONE

Abstract

Records show that the tidal length of the River Neath has been used as a trading harbour for at least the previous thousand years or-so; from the mid seventeenth century, trade was substantially increasing with no signs of abatement. Although concurrent harbour improvements had been undertaken, more significant improvements were necessary to address both current and new urgent needs if Neath were to take full advantage of this potential. By the mid-nineteenth century, although Neath had its own shipping facilities near the town bridge and Brunel's Briton Ferry dock was under consideration, much financial interest and potential, resided at the wharves further upriver from the dock, particularly those between the Red Jacket Pill and the Mines Royal Works. Based predominantly on contemporary reports, in particular those recorded by the Neath Harbour Commissioners (unless referenced otherwise), this article chronicles their efforts from the mid-nineteenth century up to the end of World War One, to improve facilities between the Red Jacket Pill and Neath town. Particular emphasis is given to the schemes that were considered to build a Floating Dock between various sections of the river, with a more detailed account given of the scheme that was eventually adopted, which commenced in 1874 and was concluded in failure during 1901. Although the project was largely completed, it is considered here that failure was due to a number of contributory financial, personal and time management factors, exacerbated by an accident which occurred at the lock during the latter stages of construction. The fate of the various structures and features of these works that remained after closure of the project are presented, along with their current status.

1.0 Introduction

The tidal length of the River Neath which had been used as a harbour over the last thousand years or-so, increased significantly from the mid-seventeenth century. For example, early advantage was taken of the relatively easy shipping routes to Cornwall resulting in convenient exchanges of coal from the Neath area serving to fuel Cornish tin and copper mines, with copper ore being returned to feed the growing number of copper-smelting facilities of South Wales. To manage such extensive turnover, the first Neath Harbour Act of Parliament, 9th July, 18001 established Neath Harbour Commissioners (NHC) as the body responsible for licensing pilots and hoblers (sic) (those who towed canal boats) along the tidal section of the river as well as controlling their duties, fees and many other associated activities.

Figure 1 The first Neath Harbour Act of Parliament, 1800 establishing the founding of the Neath Harbour Commissioners (NHC)

Figure 1 The first Neath Harbour Act of Parliament, 1800 establishing the founding of the Neath Harbour Commissioners (NHC)

The governing body of the port, NHC2 '...is composed mainly of ex-officio representatives of the different works, estates, and interests in the neighbourhood, together with eleven elected commissioners, representing the town and trade of Neath itself.'

2.0 The Need to Improve Neath Harbour

The entire (working) tidal harbour of the River Neath, extending from Giant's Grave to the town, was doing relatively well compared with its main competitor, Swansea, up to the mid-nineteenth century. However, the sand accumulations and shifting sandbanks along the meandering course of the river to the sea from the town resulted in a constantly changing navigation channel. Plus, the inability of ships to rest securely at low tide at the many wharves along this length was becoming deleterious to business. By 1815 vessels of approximately 200 tons burthen,† were capable of carefully navigating up to the town, although the number and size of shipping was steadily increasing during the industrial expansion in the area necessitating physical changes to the Neath Harbour facilities.

† burthen - an obsolete nautical term for the tonnage of a ship being a volumetric measurement of cubic capacity which estimated the tonnage of a ship based on length and maximum beam or based on the number of tuns of wine that it could carry in its holds.

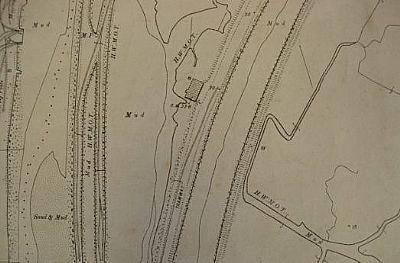

The river course to the sea from Neath is not straightforward and has basically remained as of the mid-nineteenth century, figure 2(a). The river is tidal approximately up to the weir at Aberdulais although shipping generally ceased at Neath due to the obstacle of the river bridge. In the passage to the sea from Neath, highlighted in figure 2(b), there is the need to navigate the right curve after passing Melincrythan then a sharp dog-leg left to enter the relatively smoother remaining route to the sea.

Figure 2 Modern view3 of the meandering course of the River Neath (a - left) Between mouth of estuary and Aberdulais weir (top right) (b - right) Expanded view of dog-leg near to Briton Ferry

By the mid-nineteenth century although Neath had its own shipping facilities near the town bridge much of the financial interests lay at the river wharves nearer to Briton Ferry, mainly after the dog-leg to where the group of modern buildings are seen to finish on the west bank as shown in figure 2(b). At that time, the increased building of both railway and canal networks were giving businesses alternative options to a difficult river route. So, if increased shipping was to be considered an integral part of the future of Neath then this necessitated the consideration of improving the navigation along the river [the responsibility of NHC]. The efforts of NHC could be grouped over two distinct periods, 1842-1873 and 1874-onwards.

The relative cost of their activities today is shown where considered relevant, marked *, based on Bank of England conversion rates, to give perspective to the considerable sums involved in the transactions.

3.0 Neath Harbour Developments, 1842-1873

To establish the possibilities and options to improve the harbour, NHC commissioned a report by the renowned Civil Engineer, Mr Henry Robinson Palmer (1795-1844) of 25 Great George Street, Westminster, London4 to consider the complete river course from Neath to the sea; on 29th July, 1842 a presentation of the report findings was given to NHC. The report5 stated that the ongoing river management around Giant's Grave was providing good results serving to increase the depth of the channel in that area, Palmer seeing the next opportunity as '…the increase of the depth of water throughout to the sea, and so to regulate the position of the channel in the harbour, as to give the greatest amount of accommodation for loading and discharging vessels.' To allow such an increase in depth, a series of new and improved slag embankments, along with the removal of shingle and large stones would be required along the length of the river from Neath to the sea. Palmer's plan6 is shown below.

Figure 3 (a) Henry Robinson Palmer (b) Plan by Palmer, 1842, showing new and improved embankments

A similar plan by Palmer7 also included a 'Cut' alongside the embankment opposite Lear Point to run to 'Mr Llewellins Wharf' thus offering a more direct and probably more navigable route to reach the river from a point close to the Cardiff road. It was also reported5 that, during the undertaking of this work, a suggestion was made to Palmer by 'several influential gentlemen' that a floating dock should also be considered due to the massive potential business benefits compared to the likely outlay. It was claimed that in London there was considerable reluctance by owners to send coal vessels to Neath as there was no dock. As such, ships lay on the river bed at low tide risking damage and reduced security, hence their decision to preferentially dock at Llanelli. Palmer reacted to this idea, aiming to both improve the watercourse and further encourage this envisaged additional business in-line with earlier comments. A second proposal5 was reported shortly after, converting a portion of the river to a floating dock. On 19th August, 1842 Palmer duly presented the new plan to NHC, incorporating a tide basin lock with a dock linked via a junction to the Neath canal, leading to a float. The basin was controlled by a weir across the full-width of the river located approximately in-line with the canal feed.6

Figure 4 Revised floating dock plan by Palmer 1842, incorporating a lock, weir and float

The proposed float was effectively from the new weir to Neath town, with an approximate coverage of 170 acres. The obvious main advantage was in the allowing of a much larger vessel class to navigate the river to Neath independent of the tide and capable of servicing all the wharves of the area. The costs of this latter scheme do not appear to have been reported. NHC resolved to proceed with the more basic previous general improvement harbour scheme along the already established procedures promoted by Palmer to deepen, widen, clean and alter the channel, enabling vessels of up to 300-400 tons burthen to reach Neath. There was no further mention of building a lock and basin, or Cut to 'Mr Llewellins Wharf'. It is worth noting that at this time, while residing in Neath, Alfred Russel Wallace (1823-1913), was involved over the period 1842-3 in taking soundings along the river between the sea and town to assist in this endeavour. He was of course the later renowned naturalist and associate of Charles Darwin.

The agreed requirements were incorporated into the second Neath Harbour Act, 12th July, 18438 allowing the borrowing of £20,000 (*£2,599,000), to facilitate the ongoing improvement of the harbour. The Act also served to increase the number and scope of appointed Harbour Commissioners, specifying their responsibilities along the river from 300 yards above Neath bridge along the high-water mark at neap tides [tide height occurring seven days after a spring tide] to the sea. At the Annual Meeting of the Trustees of Neath Harbour, 1845 [Palmer was by now deceased], an update of the work9 mentioned the placing of a significant amount of slag i.e. more than 107,000 tons since the 1843 Act, with the removal of approximately 6,500 cubic yards of soil/gravel. The stretch of river between Lear Point and Neath river bridge had been increased in depth by two-and-a-half feet. Further, a substantial quay wall had now been built in Neath complete with a five-ton lifting capacity crane and a watchtower built on Warren Hill to assist in piloting the river, affording a view along the complete length of the Neath Harbour area.

The noted Civil Engineer, Isambard Kingdom Brunel (1806-59), was later commissioned in 1855 to provide a report to improve the harbour.10 He basically outlined work involving the '…guiding walls of the channel...' i.e. the need to develop training banks and monthly surveys of the river to determine the next step in the evolutionary process. He predicted that the entrance to the harbour could be increased in depth by at least three-to-four feet and would be prepared to give advice on an ongoing basis. This was agreed at a Special Meeting of NHC in 1855 and the work appears to have continued in a relatively successful manner, being implemented by Brunel's chief assistant, Mr Robert Pearson Brereton, C.E. (1818-940 later of 23 Delahay Street, Westminster, London. The mural below housed aboard the S.S. Great Britain was painted in 1997 based on a portrait of Brereton housed in Bristol Technical College.11

Figure 5 Robert Pearson Brereton (left) with IK Brunel

Brereton had worked for Brunel since 1835, becoming his chief assistant in 1847, continuing until the death of Brunel on 15th September, 1859. At this point it appears that the Neath Harbour work and the role of Brereton, who went on to complete many of Brunel's unfinished works, were suspended. It was claimed12 that this ongoing delay had caused much of NHC navigational gains to be lost and advised the appointment of a successor to Brunel as soon as possible. The work eventually continued under Brereton who in 1862, reported6 that the 800,000 tons of slag used in the embankments to that date had both constrained the river and reduced the tendency for the shoaling of sands with the recommendation to continue the process so as to result in a straighter run to the sea. On 3rd November, 1865 the new Harbour Master was announced13 as Lieutenant Gwyn Lewis, who would play a significant role for many years in Neath Harbour developments.

During 1870, the subject of Neath having a floating dock was mooted once again.14 The reason was that the high volume of current trade was being restricted despite the new railway and canal routes, which were failing to meet demand, coupled with the continued attendant reluctance of shipping to use the river due to the limitations of a tidal harbour, as aforementioned. It is noted15 that 2,337 of the 2,635 vessels using the harbour over the year ending 31st March, 1872 were less than 150 tons, thereby strengthening the argument for improvements to enable larger capacity shipping, although it was later claimed16 that steamers up to 400-500 tons and maybe more could navigate to Neath at certain tides. On 27th May, 1872 at the request of NHC7 Brereton and Lewis were charged '…to prepare a scheme for floating the river from Neath downwards.' A report, 'Floating of the River Neath', was subsequently presented by Brereton on 30th September, 187217 along with the plan below.

Figure 6 Plan of 'Proposed Floating and Improvements of the River Neath' by Brereton, 1872

Due consideration had been given to drainage of the low-lying land either-side of the river upstream, the proposal of now installing a weir with a navigable entrance near to the Cwrt Sart marsh, as shown in an enlarged portion of the same plan;

Figure 7 Detail of the floating dock of Brereton, 1872

Referring to Figure 7, the working of the float was explained thus:- 'The entrance to the floated river would be by a lock of sufficient capacity for serving as a half-tide basin. This would be 300 feet in length, between the gates, and 130 feet in width, which would admit of several tiers of vessels at the same time. The basin would be used as a lock for passing vessels during low neap tides, and until the water reached the level of the float inside, after which, and throughout the springs, vessels could sail freely through the entrance basin. The width of entrance gates would be fifty-five feet. A regulating weir would be constructed across the present channel of the river, and provided with suitable sluices for letting off excessive floods, and so much of the spring tide water as may be shut in for the purpose of scouring the river channel below.'

The location and size of the weir was stated as being at the most appropriate height to allow the river upstream to back-up, such that ships could always navigate to the river bridge at Neath without the need for tidal waters. This would maintain a high neap tide depth, slightly less than nine feet below the Corporation Wharf of Neath town. The floating basin would be effectively two-and-three-quarter miles in length and enhance the opportunities for all the riverside industries of the time including Neath Abbey and Dynevor Coal Stages, Crown and Mines Royal Copper Works, Neath Abbey Works plus all the various wharves and quays at Neath. Thus, spring tides, measured at eight-to-ten feet above neap tides, would not be impeded and flow as always, up to Aberdulais. Dredging downstream of the weir would be required to maintain a depth of 25-27 feet at spring tides at entrance to the float and 15-17 feet at low neaps. The minimum depth at the float entry would be 18 feet, approximately 16 feet at the aforementioned Coal Stages and 12 feet at Neath; here, the spring tides would result in a depth of 17-19 feet following initial dredging of about three feet. It was also reported by Brereton that the ongoing maintenance work continued to be effective. Further, any concerns regarding vessel manoeuvrability restrictions due to the lack of tidal waters could now be largely obviated by the use of modern steam tugs to move ships around the float if necessary.

The costs covering the three key areas of works i.e. deepening of the river channel between the Briton Ferry Dock entrance and the proposed entrance to the float, construction of entrance lock basin and approaches combined with the regulating weir, deepening of the river up to Neath river bridge, was estimated as £80,000-£90,000 (*£9,251,000-£10,408,000) although it was later established that modifications to sewerage outlets would also now be required, adding to costs. One concern was that sewage would arrive at the weir and sink, though Brereton believed that it would carry-over and not be retained. A meeting of NHC later that year18 agreed to the raising of a Bill to undertake the work. A number of objections were raised by affected parties and although these were subsequently addressed it was not without very significant modifications to the original plan. The resultant proposed Bill of 187319 included 'A Lock and Entrance Basin…and a regulating weir…(with) and the partial impounding of the river.'. Also incorporated was a 'Floodwater Cut or Drain' from the bend in the river, approximately 650 yards below the Melincrythan Quay, across the marsh to the Cwrt Sart Pill to further assist in sewage management. The need for associated railways, approach roads, other works, etc. to service the harbour was identified and incorporated into the plan.7

Figure 8 The Brereton plan of 1872, updated with railways, etc. for the Bill of 1873 (a - top) Full map (b - above) the area showing weir/lock and floodwater cut

When the Bill was brought before Parliament on 20th March, 1873 it was argued20 that the potential of such a harbour was vast and £160,000 (*£17,791,000) would be sought to complete all necessary works. Additional supporting evidence was detailed e.g. existing coal mines were being unsatisfactorily serviced by the railways and Swansea Harbour was overcrowded such that business was being transferred elsewhere, also, there were still as-yet un-worked mines to be developed; vessels were still lying on mud at low tide and it was becoming increasingly difficult to obtain insurance, loading in such a position being very risky. Although Briton Ferry Dock was initially considered a boon to the area circa.1846, it had since been allowed to silt-up by four-to-five feet thereby reducing the draught available; the dock was also limited by the tide as it had no inflow of water.

However, this modified version of the Bill was ultimately thrown-out due to the money-raising scheme presented by the proposers i.e. simply borrow at 5% interest, with their likely income from tolls etc. being deemed unsatisfactory21, the Parliamentary statement reading22 '...the committee are not satisfied that there is any reasonable approach to certainty that the promoters would be able, if the Bill were passed, to obtain the means of executing the works proposed…' It was hoped that by modifying the Bill to address the concerns raised in Parliament it would then be carried23 but it was now surprisingly opposed by Lord Dynevor who had significant interests and owned key locations in the area. The wharves of the Dynevor Coal Company shipped the largest proportion of coal on the river.24 There were no prior indications that such objections, e.g. loss of land, would be raised and the subsequent requirements of Dynevor to withdraw objections were considered far too onerous by NHC. It was decided to25 '…abandon the modified scheme of floating the river on its present bed, and to fall back upon the formation of a navigable one across the Gnoll Marsh', i.e. a proposed float on the town side of the river only. NHC commissioned a report on this alternative from Brereton and it appears Dynevor was prepared to compromise on the original scheme, although when it subsequently emerged 26 that a float across the Gnoll Marsh was unfeasible and the only realistic option was the original plan, unsurprisingly this did not occur. NHC reluctantly reached an agreement with Dynevor, allowing a modified Bill to be presented late 1873. 27

4.0 Neath Floating Dock, 1874-1908

Whilst the resultant Bill included significant changes, it was at least now set to proceed. A very important addition was '…making the flood water cut navigable…' As stated in the Bill, 'A navigable cut or diversion of the River Neath...' meant the Cut was now no longer purely for excess water but was of a size '…sufficiently wide for the largest vessels to be easily accommodated…' 28 allowing shipping to pass through to Neath town bypassing the new floating dock at suitable tide depth. The opening of the Cut at the entrance to the dock would also maintain an important role of scouring the river bed. The Bill also mentioned 'A Lock and Entrance Basin…and the impounding of the water…' i.e. no adoption of a weir being used for regulating purposes. The impounding would be achieved by a dam which would divert the river into the navigable Cut. Details of the new requirements6 are shown below, including the proposed new railway lines and the area of the impounded float.

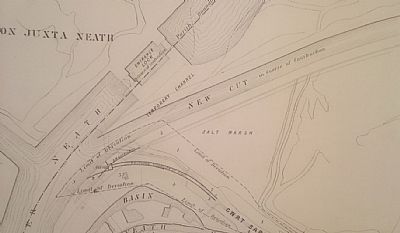

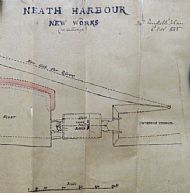

Figure 9 Plan of Neath Harbour Improvements, 1880

The only entrance into the sixty four acre basin was through the lock, all river water being diverted through the navigable Cut. The dimensions of the Cut were necessarily substantial and detailed in the Act as '…the width of the said cut at the bottom shall not be less than one hundred and two feet throughout, and the slope of the sides of the said cut shall not at any point be greater than two feet horizontal to one foot vertical, and the bottom of the said cut at the seaward and upper ends thereof shall not be higher than the present bed of the river at the same points, namely, four feet six inches and eight feet respectively above the level of the Briton Ferry Dock sill, and the bottom of the said cut shall be uniform throughout.'

The west side of the lock was effectively positioned on the Skewen bank with the east side moved significantly towards the centre of the river, which would require substantial in-fill to reach the bank of the navigable Cut towards the incoming railway line. The proposed transport routes included three new standard gauge railway lines with associated bridges; Railway No.1, with an accompanying approach road from adjacent to the Swansea & Neath Railway, crossing the Tennant Canal, would run across the Neath Abbey Marsh, over the dam/embankment that would hold the basin, then alongside the navigable Cut to eventually merge with Railway No.2 to the lock area. This latter railway originated at the South Wales Railway Great Western Railway (GWR) and crossed the Neath Canal, over a proposed bridge straddling the navigable Cut; Railway No.3 followed a similar route to the lock area although began from the South Wales Mineral Railway (SWMR) line. The Act of 1874, stated the Cut bridge was an 'opening bridge' which could also incorporate a roadway for horses, carts and carriages with adequate protection from the railway and a continuous fence along the whole length. If it did not, then the roadway would need to be constructed separately. The type of 'opening bridge' was not specified at this point, although in the later plan of 1880 [Fig.9], it is detailed as a 'swing bridge' although this was not the most appropriate description, the term 'draw-bridge' being adopted during construction. [see section 4.1.2]

The railway(s) terminated between the Cut and float, close to the lock. At this point would be constructed any necessary '… jetties, staiths, shipping stages, machinery, cranes, quays, wharves, warehouses,…' etc. for the loading and unloading at the dock, being best positioned to facilitate railway traffic. Various roadways, causeways and embankments were also included which would have been used to allow ongoing maintenance. Embankment and Causeway (E&C) No.4 ran with Railway No.1 along the west bank of the river but continued along the river bank to near the Neath Abbey Pill. E&C No.5 joined No.4 at the point where the latter continued to the pill, to run along the west bank of the Cut. E&C No.6 ran along the east bank of the dock. The estimate for construction was given by Brereton at the end of 1873 [7], as approximately £120,000 (*£13,343,000).

However, further significant items had been added to the original Bill. A lock was to be incorporated joining the Tennant Canal, located between the Crown Copper Works and the Mines Royal Copper Works, and a Graving Dock [dry dock] at the Neath Abbey Works, plus all associated drainage etc. On completion, it was stated that the embankments, sea walls, etc. would prevent both sea water and river water from entering Cwrt Sart marsh even during the highest tides. These modifications to Brereton's original plan were to eventually result in a total borrowing allowance of £180,000 (*£20,815,000) to meet the needs of the 1874 Act.

The revised version of the earlier failed Bill became the third Neath Harbour Act of Parliament, 16th July, 1874.29 It was claimed 30 that when confirmation was given to Neath '…the bells of St. Thomas' were set ringing merrily, and the loud report of cannons reverberated from all directions…' The stated time of completion for the works was seven years from 16th July, 1874.

REFERENCES FOR PART ONE

1 - ‘An Act for the Appointment and Regulation of Pilots and Hobblers for the conducting of Ships and Vessels into and out of the Port or Harbour and River of Neath, in the County of Glamorgan; for placing Buoys upon the Bar of Neath, and the Removal of Obstructions in the said Port or Harbour and River; for regulating the Mooring of Ships and Vessels therein; and for the Regulation of Porters within the said Port or Harbour and River, and within the Town of Neath’ - 9th July 1800.

2 - The Cardiff Times - 5th April 1879

3 - bing.com

4 - newsdotcom.wordpress.com

5 - The Cambrian, 27th August 1842

6 - Neath Harbour Collection - NAS

7 - Neath Harbour Collection - WGAS

8 - 'An Act for Improving and maintaining the Port or Harbour of Neath, in the County of Glamorgan', Neath Harbour Act, 12th July 1843

9 - The Cambrian, 3rd May 1845

10 - Gerald Williams, Personal Collection

11 - Brereton.org.uk/engineers.htm

12 - The Cardiff and Merthyr Guardian, 31st March 1860

13 - The Welshman, 3rd November 1865

14 - The Cambrian, 11th February 1870

15 - 'Neath and District, a Symposium', Ed. Elis Jenkins (1974)

16 - The Western Mail, 24th March 1873

17 - The Cambrian, 4th October 1872

18 - The Cambrian, 1st November 1872

19 - The London Gazette, 22nd November 1872

20 - The Cambrian, 21st March 1873

21 - The Cambrian, 28th March 1873

22 - The Western Mail, 28th March 1873

23 - The Cambrian, 13th February 1874

24 - The Cardiff Times, 6th October 1877

25 - The Cardiff Times, 28th February 1874

26 - South Wales Daily News, 11th March 1874

27 - The London Gazette, 11th November 1873

28 - The Western Mail, 12th October 1877

29 - 'An Act for enlarging and improving the Port and Harbour of Neath, and making certain Railways, Road Approaches and other Works in connexion therewith; and for other purposes', The Neath Harbour Act, 16th July 1874

30 - South Wales Daily News, 18th July 1874

END OF PART ONE

PART TWO

4.1 Specifications and Main Elements of the Floating Dock7

Comprehensive details of the 'Schedule of Quantities' for the works were provided in the specifications, with sections covering: Earthwork (Excavation); Basin, Roadways, Road and Dam; Dredging in Float, River and Cut; Slagging etc., Cut, Causeways and Dam; Entrances and Works in Basin; Entrance Gates, Machinery and Sluices; Drawbridge for Railways and Roads over Cut; Works on Railways and Roads; Permanent Way – Single Line; Railway Junctions, Signals, Permanent Way, Fittings, etc.; Junction Lock between the Tennant Canal and Float; Accommodation Works and Sundries; Two Temporary Dams at Entrances to the Basin. Additional information was provided for a number of specific categories in the 'Mode Of Proceeding With The Works' regarding the construction and use of: Permanent Fencing, Earthwork, Dredging, Embankments, Ballasting, Masonry, Mortar, Cement, Concrete, Timber Work, Dock Entrance, Gates, Sluices, Machinery, Wrought Iron Work on Dock Gates, Permanent Way, Sleepers, Rails, Fish Plates, Permanent Way Fastenings – Ironwork, Cast Iron Chairs, Laying Permanent Way.

Some of the main elements of the floating dock scheme considered in more detail here are the lock area and the navigable Cut plus earthworks.

4.1.1 Lock

The entrance channel to the lock was separated from the navigable Cut by a gangway pier, with two entrance piers located ahead of the lower entrance chamber. Following this was the entrance basin and the upper entrance chamber prior to entering the float.

Figure 10 Plan of lock area showing float, entrance lock basin, lower and upper entrance chambers, entrance piers, gangway pier (separating navigable Cut from entrance channel)

Various qualities of masonry were specified for fitting at the entrances and basin:

- Masonry Fitted Rubble in Entrance Lock and Inner Walls of Basin

- Masonry in Inverts, Paving Bottom, Gate Chain Culverts

- Ashlar in Coping, Cills, Hollow Quoins, etc.

- Portland Cement Facing to Concrete Walls in Basin

- Stone or Slag Hearting to Piers and Slag Apron

- Rubble Stone in Apron

There would also be the requirement of approximately 19,000 cubic feet of timber for the piers, framing, fenders, jetties, shipping stages and sheet piles, the latter all shod with cast iron shoes.

The gangway pier, extending from the entrance lock eastern lower wall to the entrance of the Cut , figures 10, 11(a), incorporates at its extremity, a 'Dolphin' [a structure for housing navigation aids] which was no doubt deemed a necessity at the bifurcation of the river with the associated anticipation of future traffic. This gangway pier would be constructed of timber piling and framework, maybe filled-in with slag, similar to that previously employed by Brereton at Briton Ferry.31

Figure 11 Cross-sectional views at lock area (a) Longitudinal (b) Longitudinal close-up of upper entrance chamber detailing river bed (c) Transverse view across basin including section across navigable Cut

Figure 11(b), shows the gate area at the upper entrance chamber, with the foundations below the laid base of the chamber and basin. Other features, shown more clearly in figure 11(b), may be the smaller square aperture for the gate-opening mechanism chain, although only the opening orifice is shown and possibly the larger rectangular sluice aperture which appears to run along the transverse section, figure 11(c).

4.1.1.1 Entrance Gates, Machinery and Sluices

Brereton, in part due to his long, close association with Brunel, would have been very familiar with the various types of lock gates and their different modes of operation. While no plans of the Neath lock gates or opening mechanisms have been located, associated terminology was used in meetings and reports such as: gate chain culverts, 150 tons wrought iron in dock gates, crabs for opening and closing gates, sluice valve gearing and spindles, sluice machines, eight (combined) hydraulic and hand-powered machines for opening and closing the two pairs of lock gates, chain rollers, roller boxes, gate rollers, hydraulic machines for working the sluices, air chamber deck, T-iron ribs, outer skin, sluice water-ways. Comments were also made regarding 'floating-out the gates' on high tide when ready to fit. Some contract details included:

- 150 tons Wrought Iron in Dock Gates

- 10.5 tons Wrought Iron in Straps, Screws, Spindles, etc.

- 5.25 tons Wrought Iron in Chains

- 24 tons Cast Iron in Heel Posts, Sockets, Gate Rollers and Chain Rollers, etc.

- 15.5 tons Cast Iron in Sluices, planed and fitted

- 210 cubic feet Elm in Mooring Posts

- 160 cubic feet Greenheart Timber inHeel-Posts

- 500 cubic feet Timber in Fenders, Planking, etc.

- 8 Crabs for Opening and Closing Gates

- Various: Mooring Rings, Fender, Chains, Booms, etc.

- 'Perfectly water-tight caulking' for '…whole of outer skin, both of the upper and lower sides of the gates, the air chamber deck and meeting and heel plates as well as the keel and the angle irons connecting them with the outer skin, and the water-ways of the sluices.'

- Some comments were made regarding their operation:

- Gates to move onpivot and socket under each heel-post and on a cast iron roller placed near the meeting-post and traversing upon a cast iron segmental plate firmly and accurately embedded in the masonry

- Gates worked by chains passing through chain-holes and over rollers set in the masonry and worked by crabs (8), two chains per gate, one for opening and one for closing

- Sluices in each gate with requisite screws (or similar) for their opening

- Materials and workmanship must be at least equal to those used at Briton Ferry Dock

Although figures 10, 11, are schematic, the shape of the gates shown in figure 10, appear similar to both the Plymouth dock type circa.1856 and Briton Ferry circa.1861, Figure 12 shows both of these types.31 For each, there are a series of horizontal decks and an air-chamber in each gate such that on immersion the downward pressure is reduced. At Neath, each gate had a roller near the meeting post to support part of the weight. The rollers would relieve the strain on the anchor collar at the top of the gate post and minimise any sagging at the mitre, when closed.

Figure 12 Possible Neath Harbour-type lock gates (a) Plymouth circa.1856 (b) Briton Ferry circa.1861.

The Plymouth gates, figure 12(a), also rested on rollers, whereas that of Briton Ferry, figure 12(b), relied solely on the air-chamber buoyancy. The total weight of the Neath gates, pro rata, is more comparable to the Plymouth type, although the successful adoption of the later design used at Briton Ferry, prior to the Neath works, would seem a more expedient option, with of course the addition of rollers.

4.1.2 Navigable Cut, Excavations, Dredging and Slagging

A section across the navigable Cut is detailed in figure 11(c), with the associated bridge to carry Railways No.2 and No.3, shown in figure 13. The planned depth of the Cut required approximately 16 feet to be excavated below the original bank. This vast amount of material to be removed, estimated at nearly 500,000 cubic yards, was destined to be used for the embankments, causeways, road and rail embankments, etc. and if sufficient, in-fill for the Temporary Channel (section 4.2).

Figure 13 Navigable Cut 'Draw-Bridge' with 50-foot opening span (a) Side elevation (b) Plan view

The single section across the two central spans of the bridge rested on three substantial piers constructed across the bottom of the Cut, each end adjoining the fixed sections located between the abutments and their nearest pier. Smaller additional supports were also constructed between their respective abutment and pier. Although described as a 'Draw-Bridge', in this context it is not what is considered as a typical 'lift-up' drawbridge but is actually a 'retractable bridge'. This bridge relied on the whole of the section between the two outer piers, to be raised above track height, then retracting the section over the abutments/piers, by sliding over rollers fitted atop the two piers. It would retract along the length of the crossing to one side, the left in this case, until the other end reached the centre pier, leaving a 50-foot opening to the right pier. Typically, this action would be driven by hydraulics to initially release the centre section via bolts, then raise and retract the section, with the opposite procedure for closure. Although not too clearly seen, figure 13(a) shows rollers at the top of the left and central piers. Figure 13(b), clearly shows the centre retractable section resting on the outer piers with the opening span to the right. The specification for the draw-bridge mentioned 'Machinery for drawbridge, including lifting machinery, screws, wedging, opening gear, crabs and chains'. The plan view, figure 13(b), also indicates the position of the roads either-side of the railway as required by the Act of 1874.

In addition to the excavation required at the Cut, there would be approximately a further 120,000 cubic yards to be removed at various cuttings, sidings and at the basin itself. About 165,000 cubic yards of dredging was planned around the lock and float area and around 45,000 cubic yards of slagging, etc needed for the Cut, causeways and dam.

4.2 Schedule of Work

Although much of the harbour scheme construction could continue independently, it was more complicated at the lock area which needed to be phased. During the lock and basin construction the first priority was to ensure shipping business at the wharves based upstream of the works was maintained, with minimum interruption. The area of the new lock works impinged on the existing navigation channel such that, the width of the river at that point would be insufficient to allow vessels to pass safely when the works were underway. First, a modified navigable channel or 'Temporary Channel' would need to be established allowing shipping to pass the lock construction area on the Briton Ferry side by moving the navigation channel eastwards, requiring the riverbank to be excavated on that side to increase the width to the east. It is estimated that between 75-100 feet of additional width would be required to allow building the lock while permitting safe navigation. A slag training bank would then be laid mid-river to identify the navigable channel. Once the Temporary Channel was completed and appropriate navigation regulations in force, the work at the lock area could begin.

The building of the lock area was to be undertaken 'tidal' i.e. when the tide was out, somewhat restricting the time available for working on the river bed. Laying foundations and building structures under such conditions was by then an established procedure using Portland cement, i.e. hydraulic cement, which hardens underwater and results in a water-resistant finish. This working pattern would be expected to considerably save on cost by avoiding the alternative construction of a substantial protective dam (cofferdam), with which to shield both the work and workers from the river flow at all times. Working tidal was only realistically possible due to the relatively little amount of water flowing at low tide. An example of the level is shown at the proposed basin area in figure 14, the lock lightly sketched onto the area. The approximate maximum depth at low tide was up to a few feet and even then only across a portion of the river width.

Figure 14 Details of the water level at low tide across the basin area

Once the Temporary Channel was in operation, the slag training bank would be extended to the north west of the proposed lock area to divert the non-tidal flow and lower ebb tides around the works into the Temporary Channel. This would give the best working conditions at the lock between tides. The position of the east wall bank and training banks are shown in figure 15, illustrated at the time of later demolition.7 At this time, the training banks are seen to be detached from the west bank. It is unclear as to why three banks were located at this area, maybe for increased security during working or to allow more than one access to the east lock wall from the west bank during construction.

Figure 15 Initial slag training bank along east side of lock wall (highlighted) with three slag training banks running-off northwest towards the west riverbank, shown at the time of demolition in 1908.

Until water was 'shut-out' of the basin at the final stages of construction, the tidal flow that entered the working area would naturally run seaward on the ebb tide. The lock entrance chamber walls would largely be built tidal, although a bank would be laid along the east side outer wall adjacent to the Temporary Channel as soon as practicable to avoid scouring and to form part of the eventual in-fill. Temporary concrete dams would then be built across the outer of the upper and lower entrances onto which would be placed wrought iron girders across their entire width. These girders were to be fitted into recesses formed in the outer abutments during construction. When all girders were fitted they would be 'planked' i.e. an outer construction of shuttering to completely 'shut-out' water from both the lock and basin thereby allowing all work in that area to be undertaken in dry conditions . On completion of the basin area, the temporary dams at the upper and lower entrances would be removed and the substantial lock gates floated out on a high tide to be fixed in position, virtually completing the work. At this stage the Temporary Channel would be closed, the only passage into the basin then being through the lock. With the lock and basin complete, the Cut would be opened, the dam across the river at the upper end of the float constructed as quickly as possible then the Temporary Channel filled-in. The river dam was to be 55 feet wide at high water level and 108 feet wide at the base, lined with puddle and protected by slags.

In summary, the harbour area construction as designed and planned by Brereton, a leading figure of the day in Civil Engineering, was not particularly novel or extreme and as such, no significant concerns were raised over the undertaking. Resultant NHC expectations were therefore high, in that the complete scheme could be finished both successfully and in good time.

4.3 Building the Floating Dock, 1874-1885

The financing and eventual construction of the floating dock was not straightforward and has therefore, been broken-down into discrete periods.

4.3.1 Financing and Contract Agreements, 1874-1877

When assent was given to the 1874 Act, it was deemed as a very significant moment for the future of Neath. Unfortunately, the excitement and anticipation proved to be somewhat premature, as due to financing issues, the commencement of work on the new harbour would have to wait for quite some time. The 'Commissioners' Report' of 1876,6 commented on the period since 1874, '…your Clerk (James Kempthorne) has been indefatigable in his exertions to raise money to carry out the projected works, and he is now in communication with eminent contractors and financial agents, with whom he hopes that arrangements may be made for finding the necessary capital and constructing the works.' During February, it was proclaimed that funding difficulties been resolved, albeit nearly three years following initial assent.32 Even then there was to be a further eight months until a formal announcement of the work actually starting within 14 days33 and 34 that up until mid-1877 it seemed unlikely that the scheme would ever proceed as '…no local speculators were willing to advance the money; the Commissioners themselves were unable to take the matter up; and pecuniary aid from a distance appeared out of the question.'

However, following discussions with a potential established contractor, Messrs. Vignoles & Greenbank (V&G), 15 Delahay Street, Westminster, London, NHC held a meeting on 29th September, 1877 to discuss the way forward. A proposal by V&G was accepted whereby they would undertake the contract and accept ongoing payments for their work, in bonds, at a rate of interest. Details of scheme finances were given with total estimated cost being £165,000 (*£19,671,000) and summarised 34 as: 'The cost of the work is put at £165,000. This sum is to be payable in bonds bearing interest at 6 per cent, redeemable at the end of 10 years. The contract is to be for works; exclusive of hydraulics and land. The works are to be commenced forthwith, and completed in two years and a half; at the outset three. The bonds are to be entered into for £35,000 on signing the contract, the balance of £125,000 [to be amended due to an increase of £5,000(*£596,000)] to be deposited in the names of two trustees, one to be named by the Commissioners and one by Mr. Vignoles. The bank is yet to be agreed upon. The money is to be paid out on the certificate of the engineer as the works proceed, less 5 per cent, but irrespective of the first £35,000, which is not to be subject to certificate. The bonds are to bear interest from the date of deposit. Each half-year certificates of indebtedness are to be given by the Commissioners for accrued interest to be exchanged for bonds to be issued under further powers to be obtained. Mr. Vignoles is to consent to the application by the Commissioners to Parliament for power to make a further issue of bonds not exceeding £50,000 to rank pari passu [alongside] with the £180,000, the amount in excess of the authorised issue being necessary for hydraulics, extra, and expenses.' Such financial terms were deemed necessary by NHC to allow them to proceed, although at this point the lands issue remained unresolved.

The contract exclusions included the hydraulics which would power the lock gates, coal hoists and other associated machinery, so as an addition to the earlier plans required further borrowing. Although not mentioned explicitly, there would have been the need to supply water into the float when the gates were closed to regulate and maintain float depth on water losses that would occur through gates, etc. Whether this would be provided by pumping via the Hydraulic Engine House (HEH), section 4.3.3, from the Cut or river, or a feed from the Tennant Canal is not known. Prior to contract acceptance on the 29th September, 1877 concerns had been raised over the unknown costs of hydraulics but the scheme was nonetheless approved.

A report in October 35 recognised '…almost insurmountable difficulties…' and '…inexhaustible patience…' of NHC regarding the obtainment of financing for the scheme and commented that they '…have finally entered into contracts via eminent engineering firms for the construction of the entire works, which are to be commenced forthwith, and to be completed within three years'. Also mentioned in the accompanying description of the works was a lighthouse at the entrance along with a very positive statement that the potential of the dock was sufficient to accommodate the largest vessels of the Bristol Channel. The works were to be undertaken under the superintendence of Brereton; the Resident Engineer (on-site) would be William Bell, C.E., (1818-1892), moving-on during 1880; Assistant Resident Engineer George Edward Wilson Cruttwell, (1857-1933), articled to Brereton at the time and moving-on during 1879, he would later be one of the company partners at Sir John Wolfe-Barry et al, see section 5.0; George Holland Erskine, (1858-1886), Engineer articled to Bell at the time and working on this project, moving-on during 1880; the V&G engineer overseeing the construction would be William Gill, C.E., (1843-1901), who would move-on during 1879. The first cheque for V&G was raised on 10th October, for £5,000 (*£596,000), this being a loan to begin the work.

It was now late 1877, more than three years after the Act of 1874 was given assent but at last a contract was in place to begin construction. Crucially, the lands, principally owned by Dynevor, Gnoll trustees and the Earl of Jersey still needed to be obtained by NHC and made available to V&G at the earliest opportunity. Until then any significant work could not commence.

4.3.2 Work Begins on the Floating Dock, 1877

Even though all lands were not yet in the hands of NHC, to mark the occasion of work commencing, a 'Cutting The First Sod' ceremony on 25th October, 1877 was, ironically, undertaken by Lady Dynevor, at the north end of the proposed dock '…between the railway and the river, near Mr. Young's flour mills.' and details of the huge town-wide decorations and festivities of the day were comprehensively reported. 36 37 The ceremony was watched by thousands of spectators; Lady Dynevor, having been presented with the inscribed silver spade to be used in the ceremony was reported to have '…cut a sod and dexterously wheeled it to the limits of the tent amid the cheers and the crushing of the crowd.'Apparently Lady Dynevor '…turned the first piece of turf in an artistic manner and placed it in a small wheelbarrow...' a specially-made, mahogany wheelbarrow. Events included the somewhat foreboding act of Brereton bending the silver spade while undertaking his cutting duties! The bands '…played 'Rule Britannia', and a volley of guns on the adjoining hills was discharged in honour of the event.' The following luncheon held at the Alderman Davies School was attended by 250 or-so local dignitaries, business representatives, NHC, etc. and included Mr. John Greenbank of V&G. The press reports assured that the joy and relief of those attending this ceremony had been captured for posterity and could not be underestimated.

However, a series of Special Meetings were called by NHC during April, 1878 to discuss with V&G issues that were giving cause for grave concern. It appears that V&G had proposed returning the £5,000 loan provided earlier by NHC to begin the work, which had by now already been delayed six months, basically since the ceremony. This action implied V&G were seeking to terminate the contract without any significant work being completed. Agreements had still not been reached by NHC in obtaining land from the Gnoll trustees, Dynevor, or Jersey, hence limited progress could be made by V&G. It was agreed at these meetings that once NHC received land valuations that V&G should begin work immediately and not await conveyance. NHC promised to do everything they could to allow a proper start on the project to begin. May, 1878 saw a new public draft statement regarding the works explaining advantages, increased traffic, income etc. in readiness for the upcoming money-raising campaign; V&G requested to be indemnified from any liabilities from the new money being raised and fresh terms were to be entered-into with NHC.

Now that work was ostensibly underway, the fourth Neath Harbour Act, 4th July, 1878 38 was necessary for NHC to achieve further borrowing powers of £70,000 (*£8,521,000), as stated '…the said sum of one hundred and eighty thousand pounds will not be sufficient to defray the expenses which the Commissioners have incurred and are about to incur in constructing and completing the several works…'. The Act also included details of the 'Heads of Arrangement' agreement with GWR, partly necessitated by the need for additional funds as noted '…the Commissioners are unable to raise the capital required to construct the said intended works, and in order to enable them to raise the necessary capital, or part or some parts thereof, required for the construction of the works, have applied to the Company to take on lease from the Commissioners the wharf or quay frontage and land…'. The arrangement also detailed the depth of the sills, 'The inner sill of the lock to be laid at a depth of not less than twenty-seven feet, and the sill of the basin entrance at a depth of not less than twenty-seven feet, below the level of high-water ordinary spring tides…' this high-water level being twenty seven feet above the level of the Briton Ferry dock sill.

A 6% 10-year mortgage scheme was offered by NHC in May, 1878 7 to cover the increased borrowing of £70,000 and claimed that the new dock would be suitable for vessels of 2000 tons at any time. It also noted that GWR would be in direct communication with the 'New Dock' and had taken considerable frontage while agreeing terms for the '…erection of hydraulic and other power for the purpose of facilitating shipments'. Although still not naming V&G as the contractor, the notice for the mortgage scheme stated that their payment terms for the, at that time now estimated £195,000 (*£23,737,000) scheme, was extremely positive '… and the Contractors have agreed to accept payment entirely in the 6 per cent. Mortgages; thus giving the greatest possible proof of their confidence in the success of the undertaking.' Nearly everything was now in place it seemed, barring the acquisition of 100 acres of land and total finance; borrowing potential was at £250,000 (*30,432,000) plus the £20,000 allowed from the Act of 1843. However, it was reported during October,39 that a gang of labourers had been discharged from the New Works and that this was a bad omen, no other details being provided. Work, or at least planned work, was eventually stopped by V&G around February, 1879 [40] due to continued difficulties associated with obtainment of the lands promised, despite the landowners originally expressing their approval and support of the scheme. Despite all financial terms having been agreed, V&G stated on 17th April, 1879 that NHC had not paid them the next interest due and only when paid would they put men on the ground, which would be done within a week from that date, or within a day if NHC advised they would need longer. In turn, NHC claimed that the little amount of interest V&G had been paid so far was commensurate with the little amount of work V&G had completed! This did not bode well. The following month saw the dispute escalate with V&G claiming default on payment '…but if continual difficulties are placed in our way they must seriously interfere with the success of the undertaking'. By now, NHC did not believe the works would be completed within the contracted time based on the limited progress so-far and the contract was terminated by NHC, although V&G did not give-up the contract. There was now no contractor and substantially incomplete finance; nearly five years following assent of the 1874 Act, still no substantial work had begun.

NHC attempted to fund the project themselves once again and in June, 1879 advertisements for tenders were sought for 10-year 6% mortgages up to £200,000 (*£25,415,000) to add to the £70,000 already available.41

Importantly, it was also emphasised that the necessary lands were now controlled by NHC.41 Incorrectly reported however, was that completion would be in about 10 years, this actually relating to the 10-year mortgage. Although it was reported mid-1879 42 that progress on the works up to then was slow, there was the comment that NHC gave '…a pledge of more vigorous action'.

Importantly, it was also emphasised that the necessary lands were now controlled by NHC.41 Incorrectly reported however, was that completion would be in about 10 years, this actually relating to the 10-year mortgage. Although it was reported mid-1879 42 that progress on the works up to then was slow, there was the comment that NHC gave '…a pledge of more vigorous action'.

Figure 16 Report, 21st June, 1879 indicating NHC were actively seeking a suitable alternative contractor to complete the works.

NHC now needed to consider the legal aspects of terminating the V&G contract and sought advice. This was given in January, 1880 though was not straightforward due to the very complex financing scheme. It was believed that the only defence V&G could use as a basis of stopping work would be that of the delay in obtaining Jersey's land and the non-payment of interest. Although no successful case for damages was anticipated, the likely associated publicity was deemed so harmful such that recommendation of a 'liberal arrangement' was advised as a compromise. At the same time a tender, open for two months, was received from the established Civil Engineering company Messrs. Thomas Docwra & Son, Ball's Pond Road, Islington, London for completing the work at a cost of £138,000 (*£17,537,000). If successful, Docwra agreed to be named officially as the new contractor on any prospectus and claimed the work would be competed in 18-24 months They were also prepared to input £5,000 (*£615,000) to get the work underway as soon as possible. NHC in-turn agreed to proceed to London for discussions with Brereton and the legal team to agree the next steps. Consequently, a contract had been signed with Docwra by 5th February, 1880. It was now nearly six years following assent of the 1874 Act, yet still no substantial work had been completed. Meanwhile, V&G informed NHC on 2nd February, 1880 that they would be prepared to accept £3,000 (*£369,000) immediately and £7,000 (*£861,000) within a month as settlement of their claim regarding contract termination.

Although a new contractor was ready, finance for the overall scheme still needed to be obtained, hence, on 5th February, 1880 NHC offered a 6% mortgage scheme, payable over 5, 7 or 10 years and stated 7 'A contract for the work required has been entered into with Messrs. DOCWRA & SON, on favourable terms, to be completed in thirty months; but the Contractors are of the opinion they can complete the Works much earlier.' While the previous mortgage scheme of 1878, stated that there remained the need to acquire about 100 acres of land exclusive of the floating dock, the prospectus for this 1880 model noted a significant change, '…land absolutely purchased by and in the possession of the Commissioners…118 acres exclusive…' At least the land issues appear fully resolved and even more positively, at that time, £58,000 (*£7,135,000) of the total mortgage value of £270,000 (*£33,216,000) had been allocated and applications for frontages were now being sought.

During March, V&G, while still claiming against NHC for termination of contract stated that they wished to avoid any further expense on the scheme and would now withdraw all remaining staff and plant, although it is unlikely much was left by that point. Oddly, despite the Docwra contract being signed, an alternative means of completing the works was being considered by Greenbank, as a separate business from V&G. Early April, NHC noted doubts regarding the ability [or desire?] of Docwra to commence work as there was reluctance to begin while funding remained incomplete. Costs associated with the works for the year 1880-1881 were only £57-10-0d (*£7,000). However, on 12th April, NHC provided a loan of £1,000 (*£ 123,000) to Docwra to assist in the commencement of work. During April, Greenbank also proposed a new tender, which required agreed cancelling of the prior contracts of both V&G and Docwra, with Greenbank prepared to cover any associated claims. Completion of the contract by Greenbank would be within two-and-a-half years with financial terms somewhat similar to the earlier V&G complex contract. A Special Meeting was called by NHC for 18th August, 1880 to discuss this proposed contract, although subsequent discussions with Greenbank regarding the financial element continued at great length. Eventually, a tender for £185,000 (*£22,759,000) was provided by Greenbank on 17th March, 1881 with all other details as per the earlier Docwra contract. It was not until 30th July, that NHC agreed to the tender, under certain provisos, such that from 1st September, 1881 a period of six months would be given for Greenbank to obtain finance, or else NHC would seek an alternative contractor. Whilst no date has been established regarding termination of the Docwra contract, it must be assumed this occurred prior to NHC accepting the new Greenbank terms; no documented work by Docwra has been found, however, Docwra would later seek redress for the cancellation of their contract.

Obviously the works would not now be completed within the seven years afforded by the Act of 1874, so an extension of a further three years, to 16th July, 1884, was incorporated into the fifth Neath Harbour Act, 26th August, 1880. 43 To meet both the current and anticipated additional financial requirements, this Act increased the potential borrowing power by a further £100,000 (*£12,302,000) such that it was now at £370,000 (*£45,518,000), if required. While the Act was being raised and progressed through Parliament, the finance mechanism proposed by Greenbank does not appear to have accrued sufficient support from his backers by the deadline of March, 1882 and so, once more, NHC needed to move-on. Publicly, it was claimed that progress had been in abeyance due to both the lack of finance and generally depressed state of the times. A report on 28th April, 1882 44 mentioned that new negotiations had taken place in London regarding the works and was proceeding satisfactorily. It was now nearly eight years following assent for the 1874 Act and yet again, still no substantial work had been completed. Costs for the year 1881-2 remained relatively insignificant, at £87-11-8d (*£11,000). Further, claims against NHC for termination of contracts were being sought separately by V&G, Docwra, and now Greenbank.

REFERENCES FOR PART TWO

31. 'The Life of Isambard Kingdom Brunel', Isambard Brunel, Publ. Longmans, Green & Co., 1870

32. The Cardiff Times - 10th February 1877

33. The Western Mail - 1st October 1877

34. The Cardiff Times - 6th October 1877

35. The Western Mai - 12th October 1877

36. The Cardiff Times - 27th October 1877

37. The Cambrian - 26th October 1877

38. 'An Act to enable the Neath Harbour Commissioners to raise further Capital, to authorise and confirm agreements between them and the Corporation of Neath, and the Great Western, the South Wales Mineral, and the Neath and Brecon Railway Companies; and for other purposes', Neath Harbour Act, 4th July 1878.

39. The Cambrian - 25th October 1878

40. The Cardiff Times - 5th April 1879

41. South Wales Daily News - 21st June 1879

42. The Cambrian - 27th June 1879

43. 'An Act for extending the time for completing the Neath Harbour Works, for authorising the Harbour Commissioners to borrow further money; and for other purposes', Neath Harbour Act, 26th August 1880.

44. The Cambrian - 28th April 1882

END OF PART 2

PART THREE

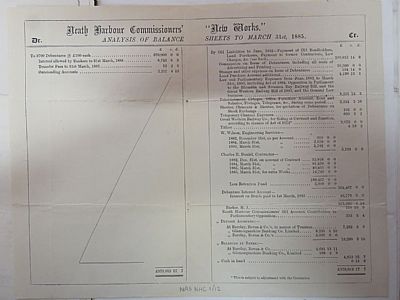

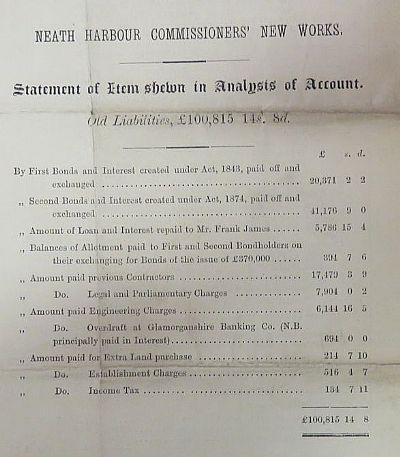

4.3.3 Construction of the ‘New Works’, 1882-1885

Following these new negotiations, the contract was subsequently moved to yet another established contractor, Mr. Charles Eckersley Daniel, 10 Dean’s Yard, Westminster, London. Daniel, having recently completed works on the extension of Portishead Docks, offered a tender of £169,700 (*£20,877,000) on 13th April, 1882. 7 Payment by NHC would be made monthly, in cash, the value based on monthly certificates of verified work completed. A retention sum of £5,000 (*£615,000) was agreed, to be half-paid on completion of work, the balance following a maintenance period of 12 months. Daniel was prepared to accept 50% of each certificate of the last £100,000 (*£12,302,000) in bonds, if cash was not available.

NHC gave notice to existing bondholders in May, 1882 that they would be consolidating all previous bond schemes associated with borrowings then totalling £370,000, into a more expedient single scheme. Bonds would be exchanged as part of a total of 3700 first mortgage debentures, each of £100 (*£12,300), with 5% interest p.a. which were to be issued and used to complete payment of all outstanding bonds since 1843, to be secured upon the tolls, dues, rates, rents, lands and all property of NHC. The 30-year debentures would have an option for bondholders to receive payment after five years. The funds, as previous, would provide for the floating dock, diversion of the river into a navigable channel and to build the required associated infrastructure.

The contract with Daniel was finally signed on 1st June, 1882, the key engineers involved in the project being agreed as:-

- William Wilson, C.E., (1822-1898), 13 Dean’s Yard, Westminster, London, named as the ‘Engineer to NHC’. Wilson was an already a distinguished engineer with considerable experience in the construction of docks, railways and bridges

- Robert Thomas Olivier Barbenson, C.E., (1845-1893), had previously worked on the Bristol and Portishead Dock developments, named as the on-site ‘Resident Engineer’

- John Fowler, C.E., (1817-1898), 2 Queens Square Place, Westminster, London, a very well-respected and established previous colleague of Wilson, named as the agreed arbitrator, should any issues arise during the course of construction that could not be resolved

- Brereton would continue as the ‘Consulting Engineer’ for NHC

Wilson would be responsible for overseeing the work of Daniel and issuing the associated verified monthly certificates which would then be forwarded to NHC for payment. Both he and Barbenson were to provide regular engineering reports, monthly as a minimum, on the status of the New Works (although reports by Barbenson ceased on 15th September, 1883 his employment continued). Following eight difficult years since the Act of 1874, with no significant progress, at very, very long last this was all about to change. It was reported45 that about one-third of borrowing power had now been attained by NHC and that Daniel would soon be commencing “…this long-deferred project…”, although by the end of June, support had gained further momentum, with approximately half of the allotted debentures being issued. At the same time, the claim by V&G for full discharge of their contract had, with interest etc. increased to £13,164 (*£1,620,000).

The New Works were now underway in earnest, Daniel really getting the project moving apace once given the go-ahead. By the end of the June, there was £4,606 (*£567,000) of plant on-site, the more major items including two locomotives (for the temporary railways), steam and hand cranes, portable and stationary engines, boilers, pumps, etc. Further major plant and materials would continue to be supplied, throughout the project, including additional pile and steam engines, cranes, boilers, barges, locomotives, etc. Wilson issued Certificate No.1 for £4,666 (*£574,000) on 3rd July, mostly for plant, with some materials and a little excavation work of the Cut and the Temporary Channel; his first report of comprehensive work, undertaken in July, during July was issued on 2nd August. In July, a further £3,530-6-10d (*£434,000) was paid for materials and work completed, with £389-15-0d (*£50,000) for additional plant. In August, particularly due to the increasing excavation work, a further 500 navvies were needed46 as advertised. 47

Figure 17 Advert to recruit 500 navvies for Neath Harbour Works, 10th August, 1882

The advert continued well into September, whilst surprisingly, NHC were already discussing the possibility of changing the plans. The consideration was to potentially meet future needs by increasing the length of the lock by between 100 feet to 400 feet (between apex of sills) at a cost of up to £5,700 (*£701,000). While it was not thought expedient at that time, they were prepared to provide additional mooring to allow vessels of up to 300 feet to swing-around. Though it may be considered odd to contemplate changing plans as soon as work had begun, it should be remembered that the original plans were by now eight years old and the shipping industry was inexorably moving to larger, more efficient steam vessels. Without being generous, such a move should be considered forward-looking, or at least prudent. NHC also agreed to settle the V&G claim at £12,231-4-6d (*£1,505,000) on 15thAugust.

Electric lighting was now being obtained by Daniel 48 to allow night-working over winter, thereby maximising time spent on the project. A Quarterly NHC meeting on 25th September 49, detailed some critical information relating to Daniel’s ongoing works, “Plant and material to a considerable amount has been delivered on the ground. The excavation of the navigable cut has been proceeded with, as well as the preparation of a temporary river channel, which will be opened previous to the closing of the present channel, at the site where the new lock will be constructed.” Surprisingly, following the already significant delays to the project, working on a Sunday was to be minimised; the spiritual welfare of this relatively large number of workers was noted as of concern to the Neath YMCA 50, with as many as 1000 navvies envisaged at some point. It was agreed to appoint a dedicated missionary to attend to any needs. Donations to finance this service were thus requested!

NHC undertook a detailed inspection of the works in October, whereupon it was reported that all was very much satisfactory and on-schedule [51], in particular the navigable Cut and the alteration of the channel [52]. Shortly after [53], NHC announced that applications were open for purchasing debentures to cover the second half of the borrowing; it was also stated [54], “The navigable canal is already cut, the entrance lock is begun, and upwards of 500 men are employed”. Confidently, the prospectus of 27th October [7] for these debentures, stated that the whole of the outstanding bonds had now been exchanged by the existing holders and that the offer was being made at this time since 118 acres of land had been purchased. Completion of the works by the contracted date of 31st December, 1883 was claimed to be assured.

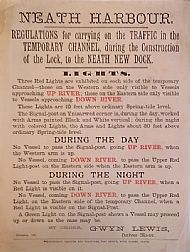

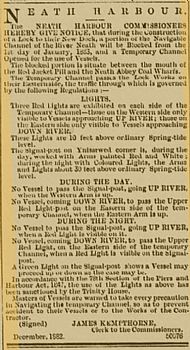

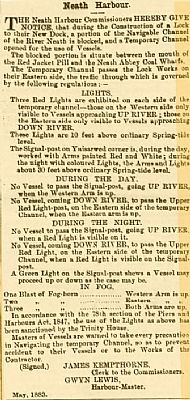

Up to 1882 year-end, employment reached about 550 men working mainly on the embankments, navigable Cut, with the significant completion of the Temporary Channel. This rapid progress meant that the latter was passed safe for purpose on 15th December. Notices were placed both locally and in many publications towards the end of 1882 7, 55, 56 detailing the safe-working procedures of the Temporary Channel that would be used during the course of lock and dock construction.

Figure 18 Notices detailing navigation regulations during construction of Neath Harbour (a) Display poster7 (b) Published notice prior to the usual navigation channel being closed 55 (b) Published notice post-closure56

By the close of 1882, a total of £36,433-12-1d (*£4,482,000) had been paid to Daniel for contracted work and very significant progress had been made.

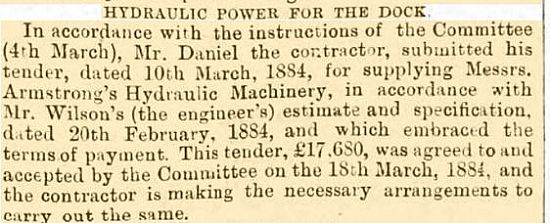

Early in 1883, notices were placed confirming the Temporary Channel regulations had been implemented, adding instructions of the requirements during fog, these notices being periodically repeated, figure 18(c). The Temporary Channel was officially opened on 1st January, 1883, allowing the lock works to begin. Barbenson reported the same month “...laying slag across the Old Channel to turn the scour into the Temporary one which has been effectively done…” and the first foundation gauge pile for the lower lock entrance was driven on 11th January. Work continued with vigour, although during February there were violent gales, floods and high tides which slowed progress considerably. At one point two pile engines were blown down and a large part of the slag bank carried away by the river freshes. Despite these setbacks, all gauge piles, along with a good amount of sheeting piles for the lower entrance, had been driven. Another locomotive was added to the plant along with three large and two small, pile engines. Wilson provided NHC with a tender for £11,900 (*£1,480,000) from Sir William G. Armstrong Mitchell & Co., Newcastle listing all necessary hydraulics for the lock and a set of machinery for working the draw-bridge, consisting of a pair of hydraulic cylinders with hauling chains attached to the bridge. The construction of the building to contain the hydraulic power supply, i.e. HEH, for the main boilers and engines would be a further £2,772 (*£345,000), totalling £14,672 (*£1,824,000). Any dockside hoists complete with auxiliary crane, capstan and auxiliary equipment would cost a further £1,850 (*£230,000) per set. A quick response and order placement was requested as the equipment design would potential affect many areas including the masonry detail of the lock. Unfortunately it was to be a long wait. NHC did advise Wilson to proceed on the basis that hydraulic power would be utilised to open the gates and draw-bridge but not yet to enter into any agreement with Armstrong. During March, work commenced on the piling for the upper entrance and excavation had begun for the foundations of the lower entrance; significant progress was being made regarding the railway lines. Something of a ‘mopping-up’ exercise also occurred that month whereby the balance of unissued debentures of £44,300 (*£5,509,000) was offered.

The Engineer’s Report to the Annual Meeting dated 21st April, 1883 [7] was very positive and stated that the navigable Cut had been excavated to within eight feet of the bottom and the banks either-side were at their proper height along the complete length. The piling for the lower cross-wall of the lock had been completed and the excavations for the foundations commenced. The piling for the upper cross-wall was advanced and all ‘Permanent Way’ (railway) materials had been delivered including those for the various bridges and other works. An additional two locomotives had been provided over April and May, with concrete starting to be laid in the foundations for the upper and lower entrance walls and their respective temporary dams. On average, about 700 men were now employed.

The NHC Quarterly Meeting, June, 1883 included a brief comment 57 relating to the ‘New Works’ “The Harbour Master was ordered to spend a sum of money for appliances for the purpose of boring to ascertain the nature of the soil under the bed of the Neath River.” This was undertaken as part of the opposition to the proposed tunnel of the Rhondda and Swansea Bay Railway (RSBR) (section 4.4.1); as reported 58, albeit closer to the mouth of the river, these borings showed one with no clay down to 14 feet, with another giving 10 feet 6 inches of sand then two feet of gravel. It is not known how these compared with original results and whether the results should have raised any concern, particularly in view of later events.

Early June, both Greenbank & Docwra settled their claim at £5,000 (*£622,000) in total for full discharge of their contracts. At least previous contractors’ claims were now resolved. Work on all areas within the basin and outside continued rapidly, although by July, the lack of a decision by NHC regarding the hydraulics was causing Daniel increasing concern. Delays in the many areas utilising hydraulics e.g. lock gates, bridges, etc. were feared because of the lack of clarity on what was to be acquired.

There was some very good news with the NHC Secretary reporting that the whole of the £370,000 sought to finance the scheme was now fully paid-up. It was around one year into the contract and Daniel had been paid £72,848-4-0d (*£9,058,000).

There was some very good news with the NHC Secretary reporting that the whole of the £370,000 sought to finance the scheme was now fully paid-up. It was around one year into the contract and Daniel had been paid £72,848-4-0d (*£9,058,000).

A significant milestone was reached in July, 1883. The progress of the works had reached an advanced stage with the next phase being that of building the lock walls.

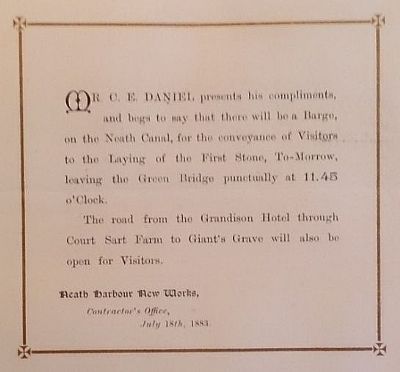

Suitable arrangements and invites were issued, figure 19 7, to attend the ‘Laying of the First Stone’ ceremony; the original plan was for 1st May but certain key attendees were otherwise engaged.

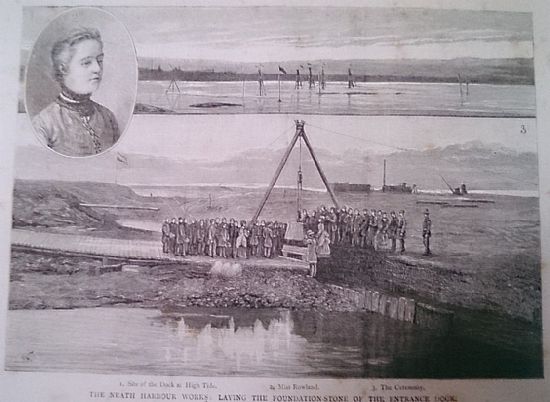

Thus, the ceremony at the entrance lock occurred on 19th July, 1883 with the first stone laid by Miss Rowland, daughter of the chairman of Neath Harbour Trust. Details of the activities were comprehensively covered 59 with a depiction of events. 60

Figure 20 Ceremony of the Laying of the Entrance Lock Foundation Stone, 19th July, 1883

Although the artist’s impression, figure 20 does show what appears to be the top of some sheet piling and maybe a gauge pile at the water’s edge, outlining the foundations of the lock. Interestingly, also shown is an inset of the area at high tide, with the area completely underwater. Nonetheless, at this point in time, despite the obvious challenge of Daniel’s workers having only hours to work on the project between tides, he believed that they had “…gone through the worst of it…” 59 The intention remained to complete the works by the end of 1883.

During September, a final locomotive was added to the already considerable amount of plant involved in the work. However, the significant delay in approving the hydraulics tender had already partly resulted in the need to apply for another Act of Parliament, with an extension of the time for completion of a further year, to 16th July, 1885. Daniel was informed on 25th September, that NHC were “disposed to accept” (but still not agreed to sign as yet) his tender of £27,800 (*£3,457,000) for the hydraulics - now including six hoists - subject to some adjustments within the original hydraulics contract. This increased tender, subsequent to that of Wilson, now incorporated the responsibility of the contractor for liaison and control over the installation, which would be undertaken by Armstrong. Also Daniel would need to accept payment of one-third cash and two-thirds in bonds, which was subsequently agreed. The reason for the ongoing considerable delay in final acceptance of the hydraulic contract was blamed on the lack of confirmation as to the number of coal hoists required by GWR.

Piling, excavation, concreting and building of associated walls continued in nearly all areas of the lock and basin up to year-end 1883, with some walls nearly up to coping level. All other work on railways, causeways etc., continued to make excellent progress, including commencement of the foundations for the piers of the draw-bridge across the Cut - this was itself now at risk of delay due to the lack of decision on the hydraulics which was still in abeyance.

Also in September, NHC discussed the best method of keeping seawater out of the Cwrt Sart marsh to avoid any future issues with the works. The Cut had by now been excavated but the east embankment stopped at the entrance to the Cwrt Sart Pill. It had not at that time continued across the pill as implied in the 1874 Act and seems only now to have been given serious consideration, with obvious associated additional costs. The proposal was to divert the pill by extending the east bank of the Cut across the mouth, though the area was not part of land already owned by NHC. The pill would then be moved southwards, entering the river underneath the extremity of the embankment. This was agreed and needed to be incorporated into the new Bill that was already underway. To meet the needs of the proposal to keep the seawater out of the marsh, apart from extending the embankment this necessitated the introduction 61 of “…a tidal flap to be fixed at the mouth of the culvert under the embankment, such culvert to be of a clear sectional area not less than 64 feet…” as shown in the submission 7 of November, 1883.

Figure 21 Details of submission regarding the 1883 Bill of the Neath Harbour Act 1884, for the ‘Diversion of Cwrt Sart Pill’, incorporating a sluice at entrance to river